Project Scope

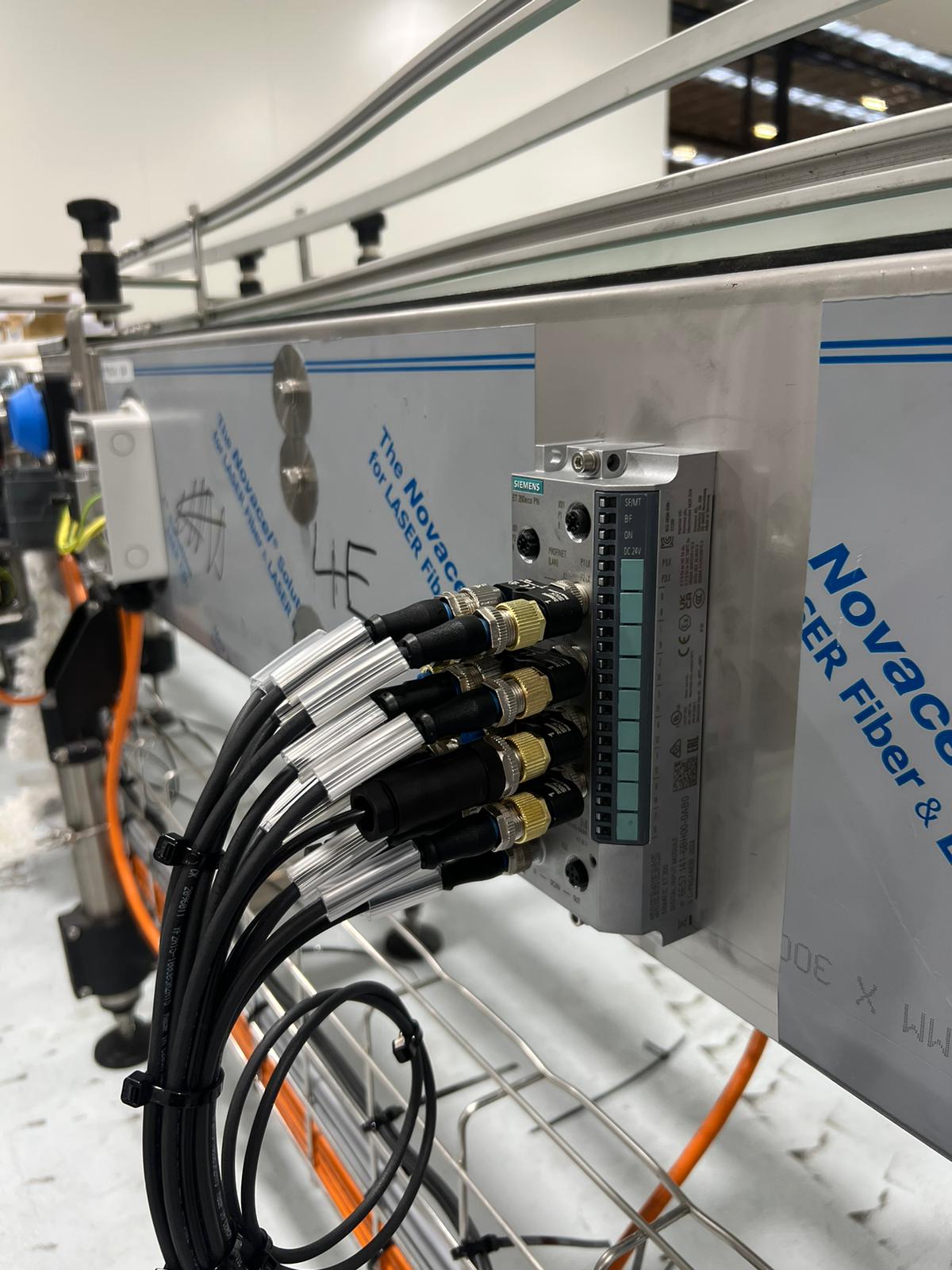

The End of Line Handling for Composite Packs project involved integrating a comprehensive end-of-line system to handle composite packs. This included integrating 25 conveyors, communicating with wrapper and strapper systems, and ensuring seamless integration with upstream equipment. Multiple sensor blocks were located around the line to enhance system functionality.

One of the main challenges was presenting the product to the robot system. To address this, we implemented a control strategy using servodrives and pneumatic stoppers to form rows of the product, which were then presented to the robot system. This process was documented in a video currently available on the home page.

The project also involved creating three safety zones, each with a safety rating of PLd SIL2, to ensure the highest standards of operational safety.

Client

Cantech Engineering / Zipform Packaging

Industry

Food & Bev

Location

Dandenong, Victoria

Duration

Jan 2023 - Dec 2023

Key Technologies Used

• Siemens S7-1500F Controller: This controller was used for its advanced capabilities in handling complex automation tasks.

• Siemens Variable Speed Drives: These drives were integrated with ProfiSafe and Profinet control to ensure precise and safe operation of the conveyor systems.

Certified System Integrators Echuca

Certified System Integrators Echuca Monday to Friday 7:00am - 3:30pm

Monday to Friday 7:00am - 3:30pm